Discover the Benefits of Aluminum Casting in Modern Production

Aluminum casting has become a pivotal procedure in modern-day production. Its light-weight yet durable nature presents considerable advantages for different sectors. The capability to accomplish detailed designs and maintain limited resistances adds to its allure. Precision aluminum casting. Furthermore, the cost-effectiveness and ecological benefits make it a lasting choice. As producers look for cutting-edge services, the duty of aluminum casting proceeds to progress. What details applications and benefits wait for expedition in this dynamic area?

Light-weight Yet Solid: The Benefits of Aluminum

Many materials are used in manufacturing, aluminum stands out due to its amazing mix of light-weight buildings and exceptional toughness. This special characteristic makes aluminum an optimal selection for numerous applications, especially in markets such as automotive, aerospace, and construction. Its reduced density allows for easier handling and transport, adding to lowered power consumption during production and assembly processes.

Moreover, aluminum's strength-to-weight proportion goes over, allowing producers to develop resilient elements without including unneeded mass. This characteristic is particularly useful in sectors where weight decrease can cause enhanced gas efficiency and overall performance. Additionally, aluminum's resistance to corrosion improves the long life of items, even more solidifying its charm in modern manufacturing.

Inevitably, the light-weight yet solid nature of aluminum placements it as a preferred product, cultivating innovation and effectiveness across multiple industries. Producers significantly recognize that these benefits can cause substantial developments in design and functionality.

Precision and Complexity in Layout

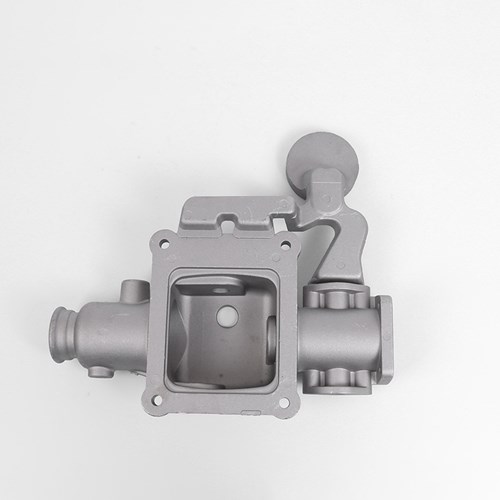

As makers accept the capacities of aluminum casting, they find brand-new avenues for precision and intricacy in style. This production process enables the creation of elaborate forms and thorough features that traditional methods often battle to attain. The fluidity of molten aluminum enables it to fill up complex molds, resulting in parts with tight resistances and fine surface coatings.

This precision is specifically helpful in markets such as aerospace and vehicle, where exact requirements are crucial for performance and safety and security. Aluminum casting likewise fits cutting-edge designs that enhance performance without endangering architectural honesty.

Cost-Effectiveness and Effectiveness

Cost-effectiveness and efficiency are vital factors to consider for manufacturers checking out aluminum casting as a production approach. Aluminum casting deals considerable price advantages due to its reduced product costs compared to various other steels (Precision aluminum casting). The lightweight nature of aluminum reduces delivery and handling expenditures, and its exceptional thermal conductivity enables quicker cooling times during the casting procedure, enhancing total production rate

Aluminum's versatility enables suppliers to produce complex shapes and layouts, decreasing the need for additional machining or assembly. This streamlining of production not just lowers labor costs but additionally shortens lead times, permitting companies to react quickly to market needs.

Additionally, the longevity and rust resistance of aluminum castings add to longer product lifespans, minimizing substitute expenses over time. Because of this, manufacturers can accomplish a balance of premium output and decreased functional expenses, making aluminum casting a significantly appealing option in modern-day production.

Environmental Sustainability of Aluminum Casting

Aluminum casting sticks out as an environmentally sustainable manufacturing alternative, especially because of its recyclability and decreased eco-friendly impact. The procedure permits the reliable usage of aluminum, a product that can be recycled indefinitely without shedding its homes. This particular significantly lowers the demand for virgin aluminum, thus decreasing and conserving all-natural resources energy consumption related to extraction and handling.

Applications Across Industries: From Automotive to Aerospace

While varied sectors remain to look for ingenious materials for production, aluminum casting has verified to be a flexible remedy throughout fields such as auto and aerospace. In the automotive sector, aluminum spreadings add to light-weight vehicle layouts, improving gas effectiveness and performance. Components like engine blocks, transmission housings, and wheels gain from aluminum's strength-to-weight proportion.

In aerospace, aluminum casting plays a substantial function in producing complex components that call for high longevity and reduced weight. Aircraft parts such as brackets, landing gear, and architectural frames utilize aluminum for peak performance and security.

Moreover, the versatility of aluminum casting enables it to deal with various other sectors, including consumer electronics, marine, and commercial machinery. This flexibility not only fulfills the details requirements of various applications but additionally supports recurring technology in manufacturing processes. As a result, aluminum casting remains a crucial player in modern manufacturing throughout numerous fields.

Frequently Asked Questions

How Does Aluminum Casting Compare to Various Other Steel Casting Procedures?

Aluminum casting deals premium strength-to-weight ratios, faster cooling prices, and excellent corrosion resistance compared to various other steel casting procedures. These advantages make it perfect for various applications, improving efficiency and performance in manufacturing.

What Are the Common Lead Times for Aluminum Casting Projects?

Typical preparation for aluminum casting jobs range from two to 8 weeks, depending upon variables such as complexity, order dimension, and manufacturing ability. Reliable preparation can aid reduce delays and boost job timelines.

Can Aluminum Casting Be Utilized for Intricate Designs?

Aluminum casting can undoubtedly fit elaborate layouts. Aluminum Foundry. Its fluidity enables in-depth patterns and forms, making it appropriate for intricate parts in different sectors. This flexibility enhances layout flexibility while keeping structural stability and performance

What Post-Processing Options Are Available After Aluminum Casting?

Post-processing choices for aluminum casting include machining, brightening, surface area therapies, anodizing, and welding. These techniques boost the surface, boost dimensional precision, and increase deterioration resistance, thereby optimizing the end product's performance and visual allure.

Exactly How Do Temperature Level Changes Affect Aluminum Casting Quality?

Temperature level adjustments significantly impact aluminum casting top quality by influencing fluidity, solidification rates, and possible issues. Rapid cooling can bring about increased brittleness, while too much warm might create warping or insufficient filling of mold and mildews during casting.

Aluminum casting has actually emerged as a pivotal process in modern-day manufacturing. As suppliers accept the capabilities of aluminum casting, they discover new opportunities for precision and intricacy in style. Aluminum casting processes commonly produce fewer greenhouse gas emissions compared to various other steel casting approaches. While diverse industries proceed to seek cutting-edge products for production, aluminum casting has verified to be a versatile solution throughout sectors such as automotive and aerospace. In the vehicle industry, aluminum castings add to light-weight car layouts, improving fuel effectiveness and performance.